Rosetta

Carbon fibre stretches from comet to machine tools

Ultra-light carbon-fibre rods used to stiffen a comet probe’s legs are now being harnessed by a German manufacturer to boost the precision and efficiency of their laser cutters.

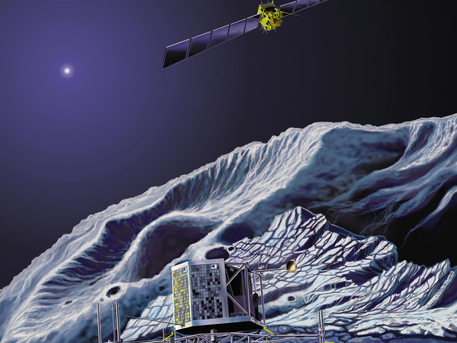

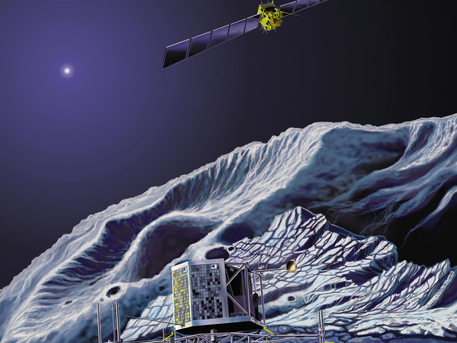

© Astrium - E. Viktor

|

The Rosetta orbiter swoops over the lander soon after touchdown on Comet 67P/Churyumov-Gerasimenko

Article Content

- » 1 - Carbon-fibre rods guarantee safe landing

- » 2 - Better cuts and customisation

Carbon-fibre rods guarantee safe landing

Right now, the rods in question are on a collision course with a comet – literally.

In 2014 ESA’s Rosetta spacecraft will end a decade-long chase through space by catching up with Comet Churyumov–Gerasimenko.

It will orbit the comet and release its Philae lander to anchor itself to the icy surface.

To ensure a safe landing, the lander’s legs are made of lightweight carbon fibre rods.

Designed by Schütze, a German company in Braunschweig, these rods are six times lighter than steel, but can be made up to 50% stiffer.

These 'sandwich rods' have a lightweight, rigid foam core wrapped in carbon fibre and coated with thin fibreglass.

“No mould is necessary, making the production of tailored rod dimensions feasible,” said director Rainer Schütze. As well as the lander legs, the folding antenna and frame of Rosetta are also based on the lightweight rods.

“The carbon fibre sandwich rods combine high strength and stiffness with very low weight,” added Mr Schütze.

Thanks to ESA’s Technology Transfer Programme, the rods’ special qualities are also improving products here on Earth.

In 2014 ESA’s Rosetta spacecraft will end a decade-long chase through space by catching up with Comet Churyumov–Gerasimenko.

It will orbit the comet and release its Philae lander to anchor itself to the icy surface.

To ensure a safe landing, the lander’s legs are made of lightweight carbon fibre rods.

Designed by Schütze, a German company in Braunschweig, these rods are six times lighter than steel, but can be made up to 50% stiffer.

These 'sandwich rods' have a lightweight, rigid foam core wrapped in carbon fibre and coated with thin fibreglass.

“No mould is necessary, making the production of tailored rod dimensions feasible,” said director Rainer Schütze. As well as the lander legs, the folding antenna and frame of Rosetta are also based on the lightweight rods.

“The carbon fibre sandwich rods combine high strength and stiffness with very low weight,” added Mr Schütze.

Thanks to ESA’s Technology Transfer Programme, the rods’ special qualities are also improving products here on Earth.

Rosetta

Carbon fibre stretches from comet to machine tools

Ultra-light carbon-fibre rods used to stiffen a comet probe’s legs are now being harnessed by a German manufacturer to boost the precision and efficiency of their laser cutters.

© Astrium - E. Viktor

|

The Rosetta orbiter swoops over the lander soon after touchdown on Comet 67P/Churyumov-Gerasimenko

Article Content

- » 1 - Carbon-fibre rods guarantee safe landing

- » 2 - Better cuts and customisation

Carbon-fibre rods guarantee safe landing

Right now, the rods in question are on a collision course with a comet – literally.

In 2014 ESA’s Rosetta spacecraft will end a decade-long chase through space by catching up with Comet Churyumov–Gerasimenko.

It will orbit the comet and release its Philae lander to anchor itself to the icy surface.

To ensure a safe landing, the lander’s legs are made of lightweight carbon fibre rods.

Designed by Schütze, a German company in Braunschweig, these rods are six times lighter than steel, but can be made up to 50% stiffer.

These 'sandwich rods' have a lightweight, rigid foam core wrapped in carbon fibre and coated with thin fibreglass.

“No mould is necessary, making the production of tailored rod dimensions feasible,” said director Rainer Schütze. As well as the lander legs, the folding antenna and frame of Rosetta are also based on the lightweight rods.

“The carbon fibre sandwich rods combine high strength and stiffness with very low weight,” added Mr Schütze.

Thanks to ESA’s Technology Transfer Programme, the rods’ special qualities are also improving products here on Earth.

In 2014 ESA’s Rosetta spacecraft will end a decade-long chase through space by catching up with Comet Churyumov–Gerasimenko.

It will orbit the comet and release its Philae lander to anchor itself to the icy surface.

To ensure a safe landing, the lander’s legs are made of lightweight carbon fibre rods.

Designed by Schütze, a German company in Braunschweig, these rods are six times lighter than steel, but can be made up to 50% stiffer.

These 'sandwich rods' have a lightweight, rigid foam core wrapped in carbon fibre and coated with thin fibreglass.

“No mould is necessary, making the production of tailored rod dimensions feasible,” said director Rainer Schütze. As well as the lander legs, the folding antenna and frame of Rosetta are also based on the lightweight rods.

“The carbon fibre sandwich rods combine high strength and stiffness with very low weight,” added Mr Schütze.

Thanks to ESA’s Technology Transfer Programme, the rods’ special qualities are also improving products here on Earth.